Products in this page

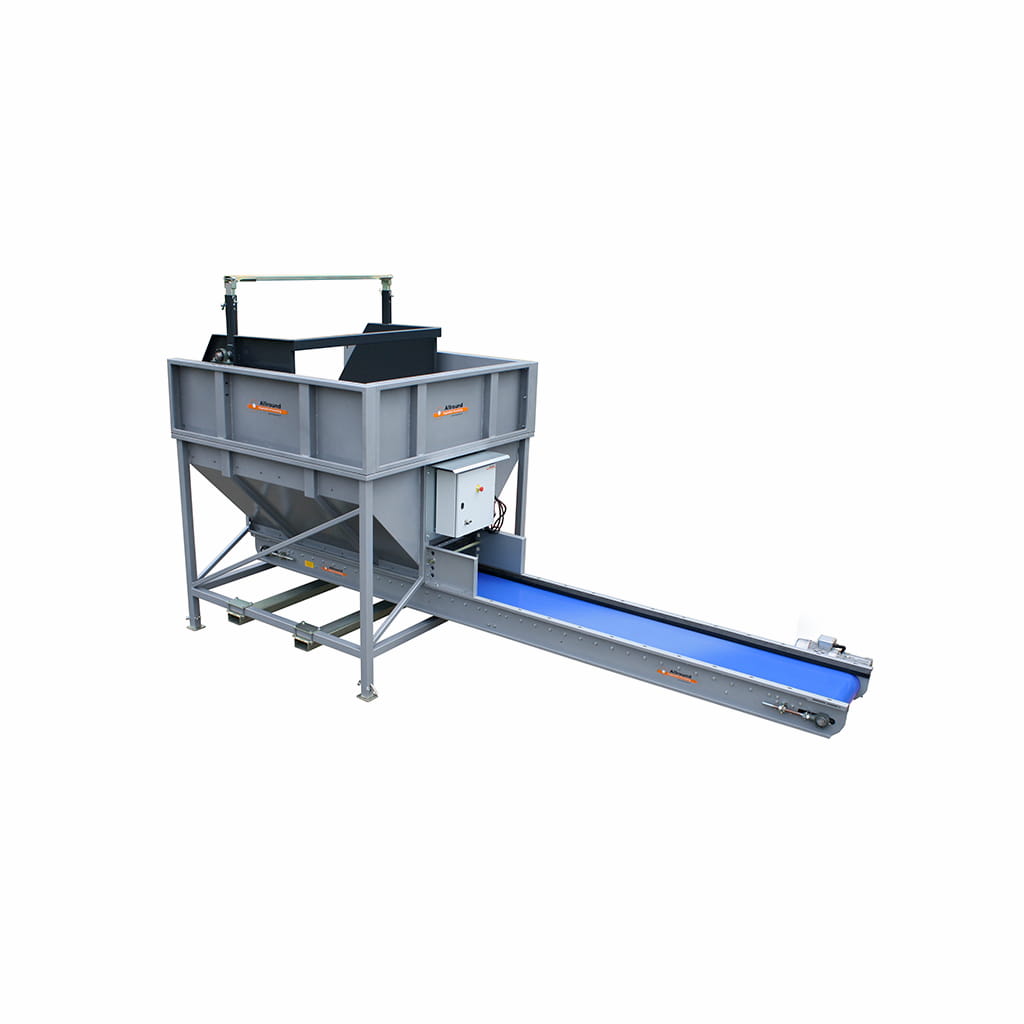

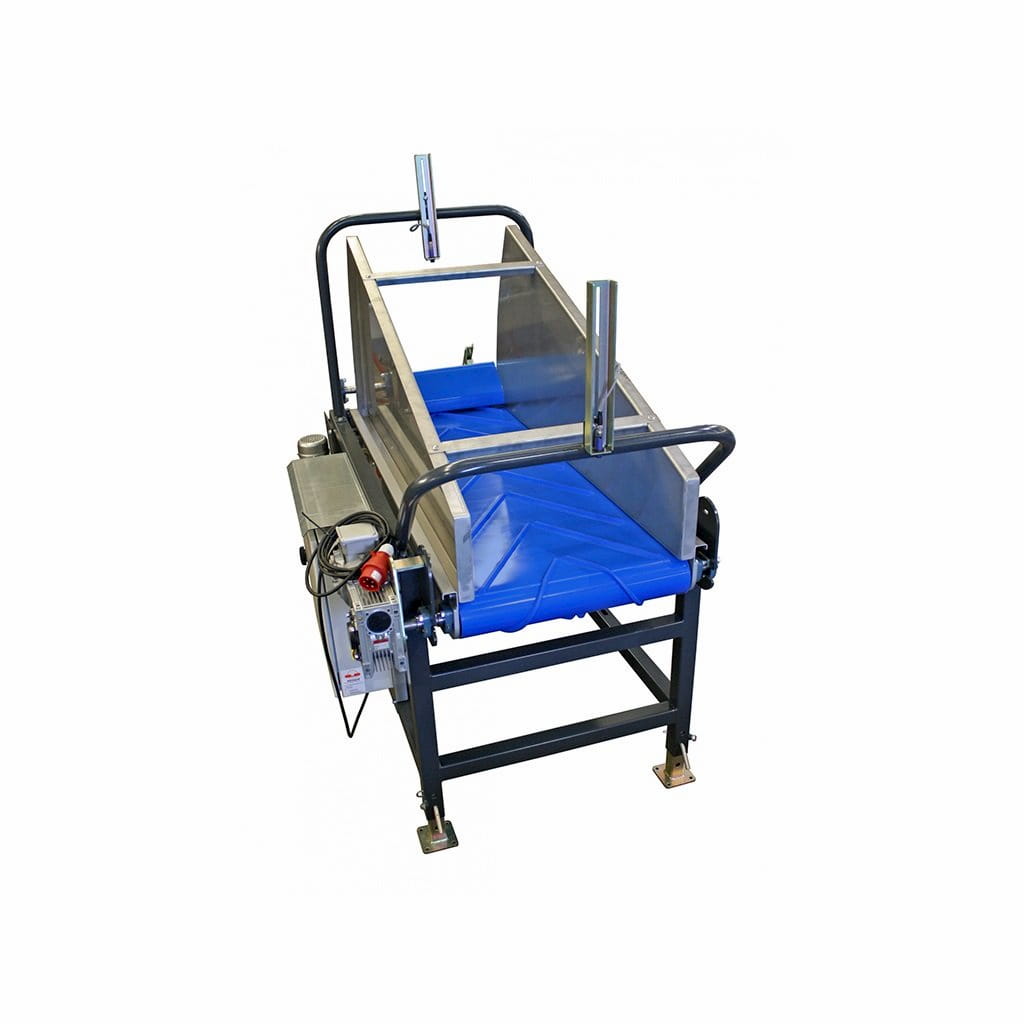

Storage Hopper - Box Tipper

The storage hopper – box system is specifically designed to provide a metered weighing and packing system for products, mainly potatoes, onions, and industry spheres.

This machine although complex does not require a lot of space as the box tipper is mounted on top of the hopper. The machine has a capacity of +/- 3 cubic meters but is available in different sizes to accommodate for larger content.

The hopper’s height can be easily regulated by removing the locking pin and adjusting the set of legs in the proper position. The box tipper is particularly designed for cubic containers with a maximum size of 1200×1700mm and a height of 1000 to 1350mm.

| Produce | 160-1.5 | 160-3 | 180-3.5 | 180-7 |

|---|---|---|---|---|

| Potatoes - Onions - Red Beet | 1.5 m³ | 3 m³ | 3.5 m³ | 7 m³ |

Receiving Hopper

The receiving hopper is made to feed the produce or acts as a buffer in loading and unloading lines of processing lines.

The hopper is constructed in a way to be easily fed by tip trailers, box tippers, and big bags.

Due to a properly adjusted angle in the machine, the flow of the products will always be even. Additionally, a frequency inverter allows you to control the flow of products appropriately.

Wet Hopper

The wet hopper is a special pre-cleaning device, also known as the Jacuzzi.

The produce drops in the water due to the soil which makes it heavy. Air coming from the underside of the machine creates bubbles which forcefully clean the products. Once the soil is cleaned off the produce, it becomes lighter in weight and resurfaces to the top where it is taken out by a web belt.

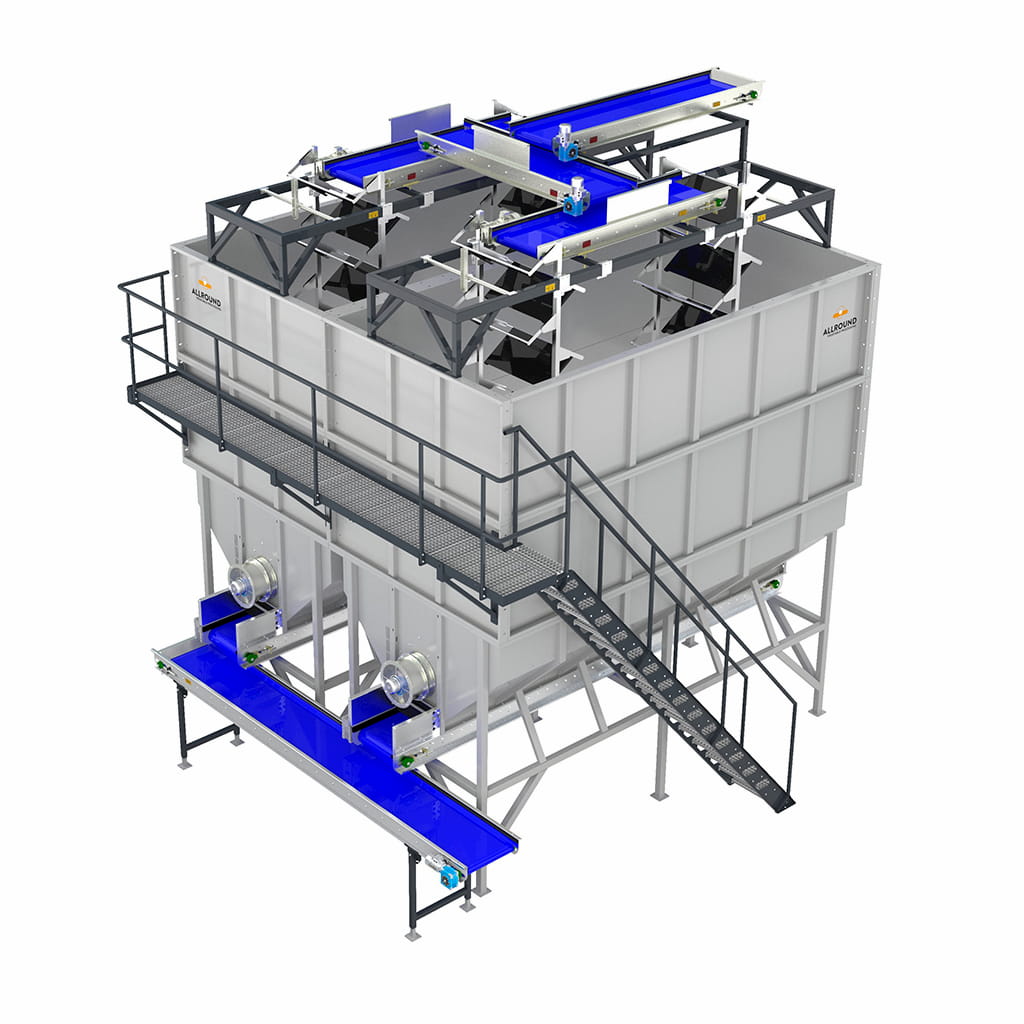

Storage Hopper

The storage hoppers act as a buffer in a processing line, or between a processing line and a packaging line.

They are built in segments and the storage capacity of the machine depends on its length and height.

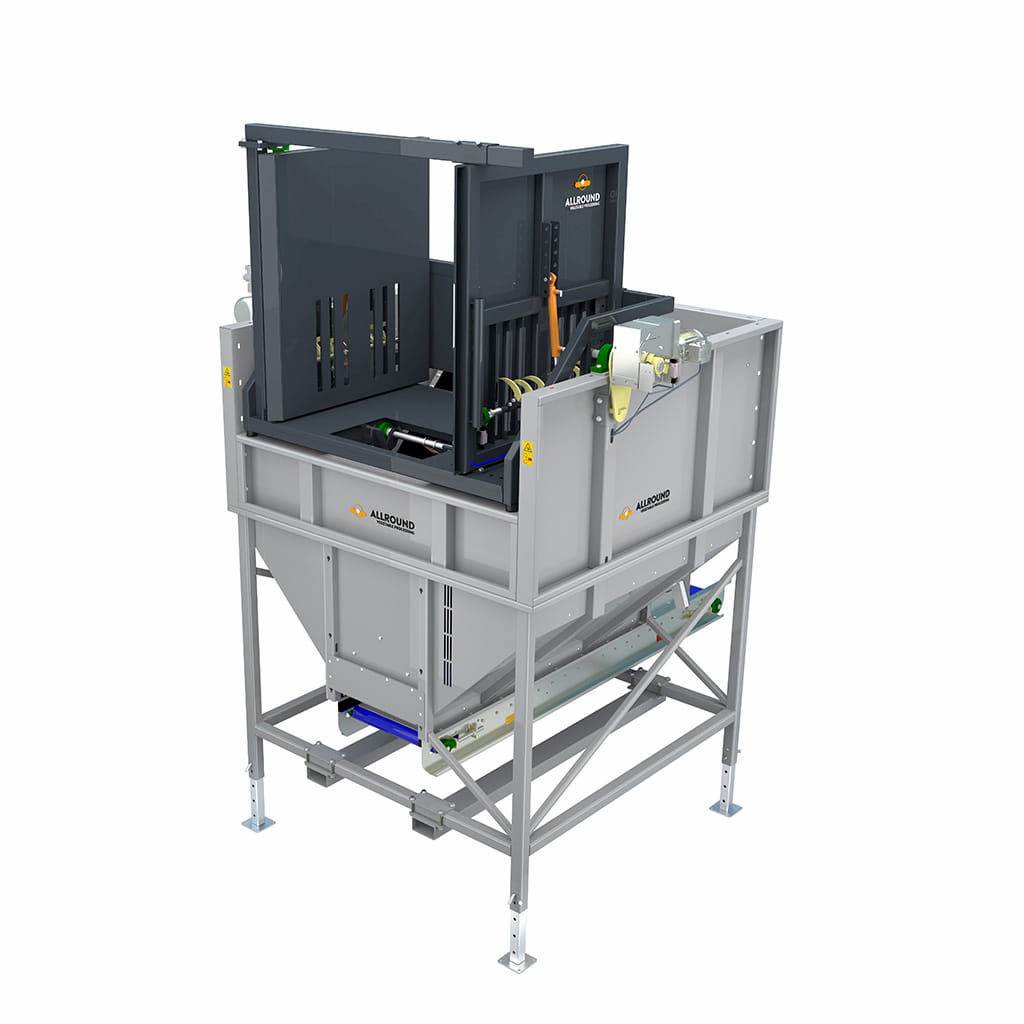

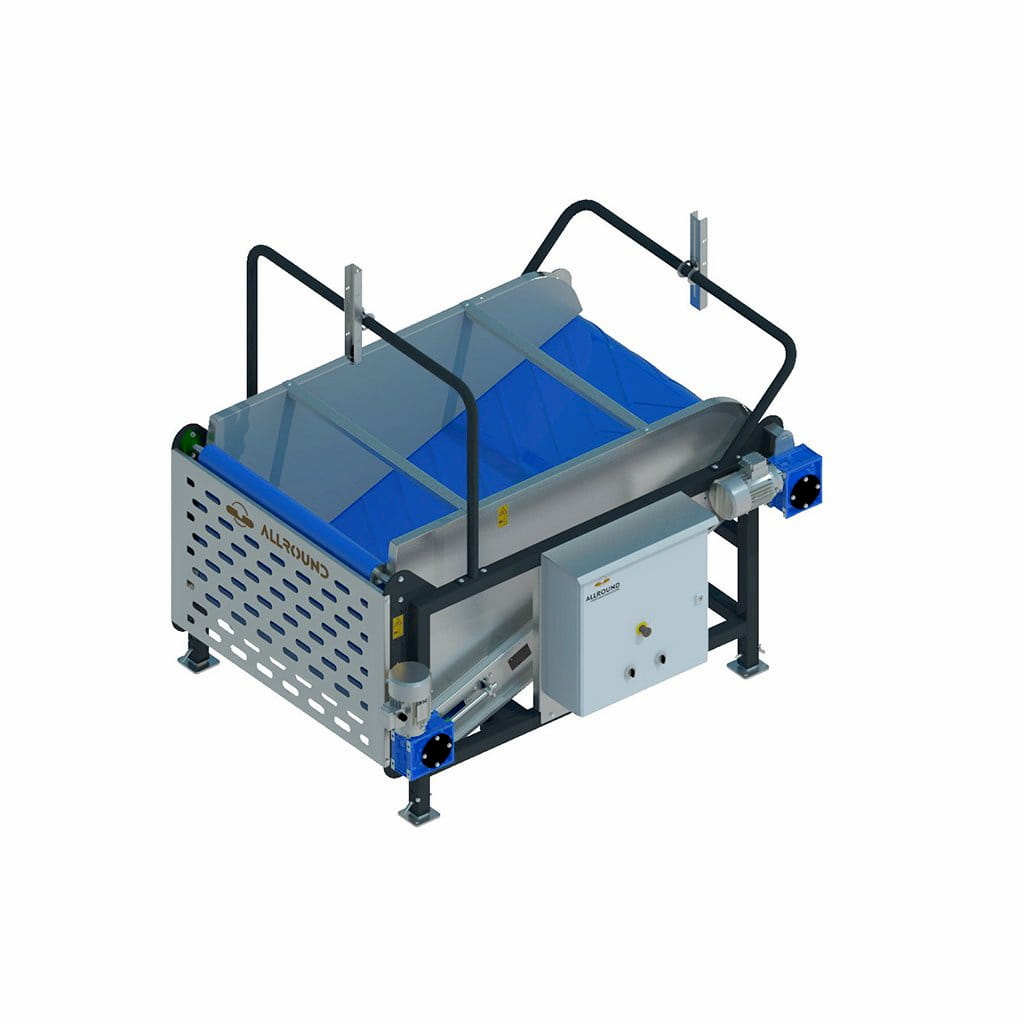

Hopper

The hoppers are made to feed the produce or act as buffers in loading and unloading lines of processing lines.

The hopper is designed to work with cubic boxes and big bags. Due to a properly adjusted angle in the machine, the flow of the products will always be even. Additionally, a frequency inverter allows you to control the flow of products appropriately. The machine is very gentle on the produce.

| Specs | B 100-300 | B 120-250 | B 120-450 | B 120-600 | B 160-500 | B 230-900 |

|---|---|---|---|---|---|---|

| Length (mm) | 3220 | 3220 | 5220 | 6700 | 5700 | 12000 |

| Width (mm) | 1834 | 2242 | 2235 | 2300 | 2700 | 4200 |

| Belt Width (mm) | 1000 | 1200 | 1200 | 1200 | 1600 | 2300 |

| Total Content | 2 m³ | 5.5 m³ | 11 m³ | 20 m³ | ||

| Effective Content | 1.5 m³ | 3.5 m³ | 7 m³ | 14 m³ | ||

| Drawing | View | View | View | - | View | - |

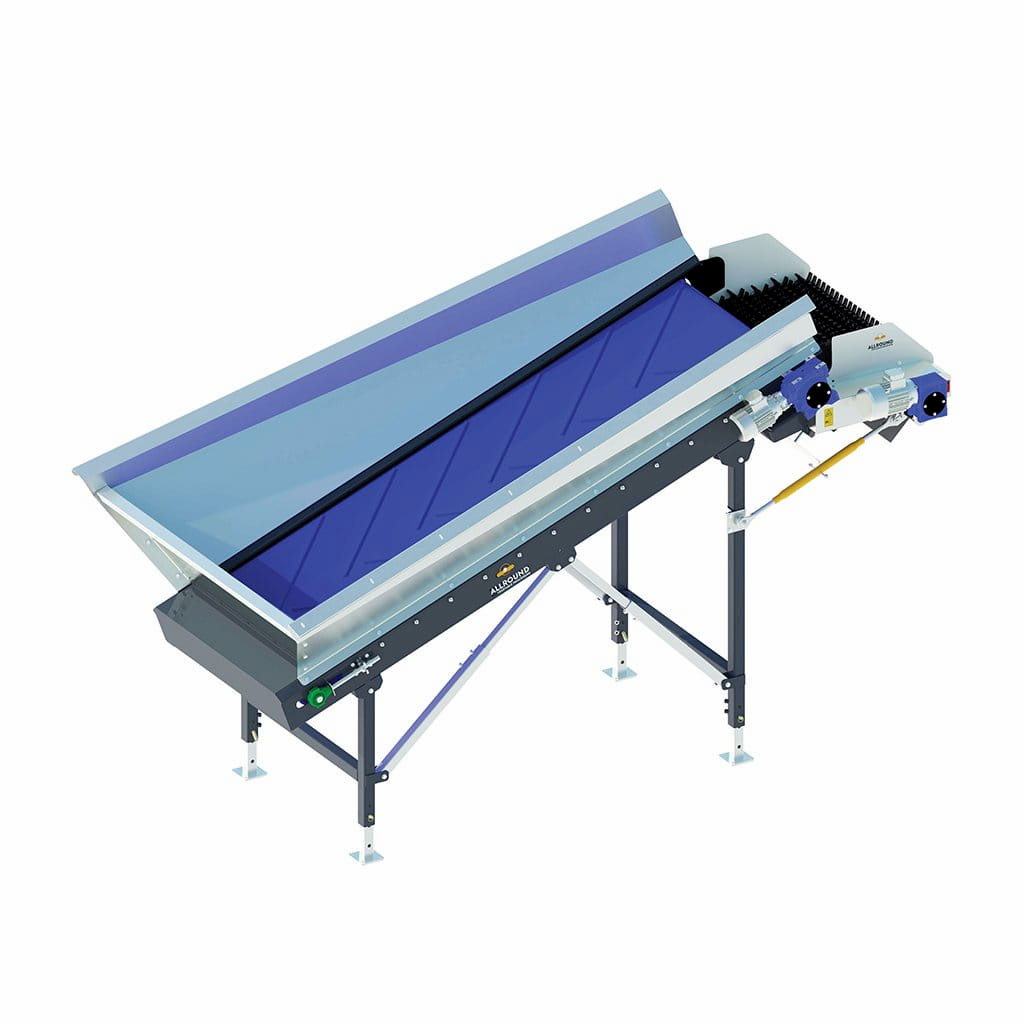

Even Flow Hopper

The even-flow hopper is designed to adjust the flow of products in a line. The even-flow hopper is commonly used in front of a weighing machine or an optical sorter.