Products in this page

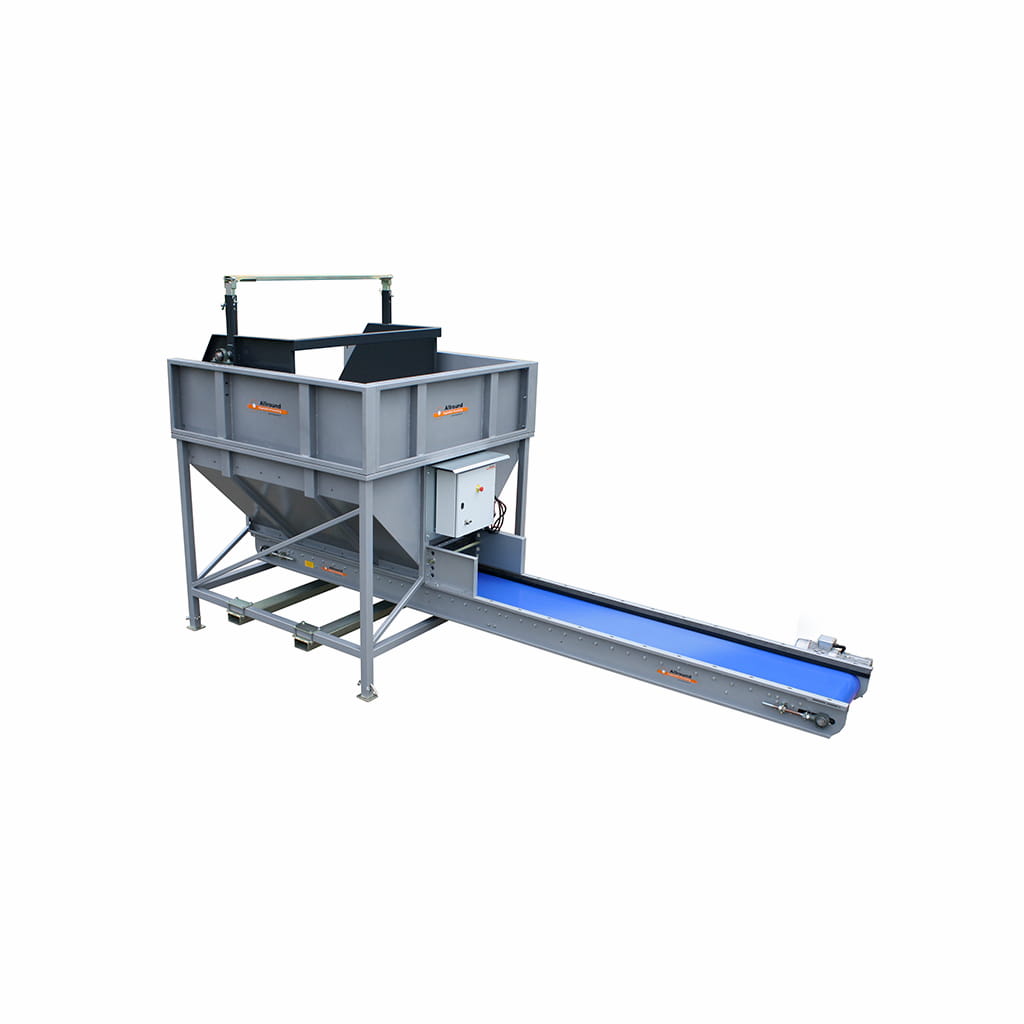

Storage Hopper - Box Tipper

The storage hopper – box system is specifically designed to provide a metered weighing and packing system for products, mainly potatoes, onions, and industry spheres.

This machine although complex does not require a lot of space as the box tipper is mounted on top of the hopper. The machine has a capacity of +/- 3 cubic meters but is available in different sizes to accommodate for larger content.

The hopper’s height can be easily regulated by removing the locking pin and adjusting the set of legs in the proper position. The box tipper is particularly designed for cubic containers with a maximum size of 1200×1700mm and a height of 1000 to 1350mm.

| Produce | 160-1.5 | 160-3 | 180-3.5 | 180-7 |

|---|---|---|---|---|

| Potatoes - Onions - Red Beet | 1.5 m³ | 3 m³ | 3.5 m³ | 7 m³ |

Box Tipper

The box tippers are made to feed processing lines or machines. The tipper places the box over the machine and slowly tilts it so that a hopper or elevator is filled.

| Specs | Z 160 | Z 180 | Z 250 |

|---|---|---|---|

| Width of Boxes (mm) | 1600 | 1800 | 2500 |

| Max Height (mm) | 3480 | 3480 | 3480 |

| Height in Low Position (mm) | 1730 | 1730 | 1420 |

| Width | 2130 | 2430 | 3180 |

| Max Angle | 140° | 140° | 140° |

| Hydraulic Pressure (Bar) | 180 | 180 | 200/220 |

| Drawing | View | - | - |

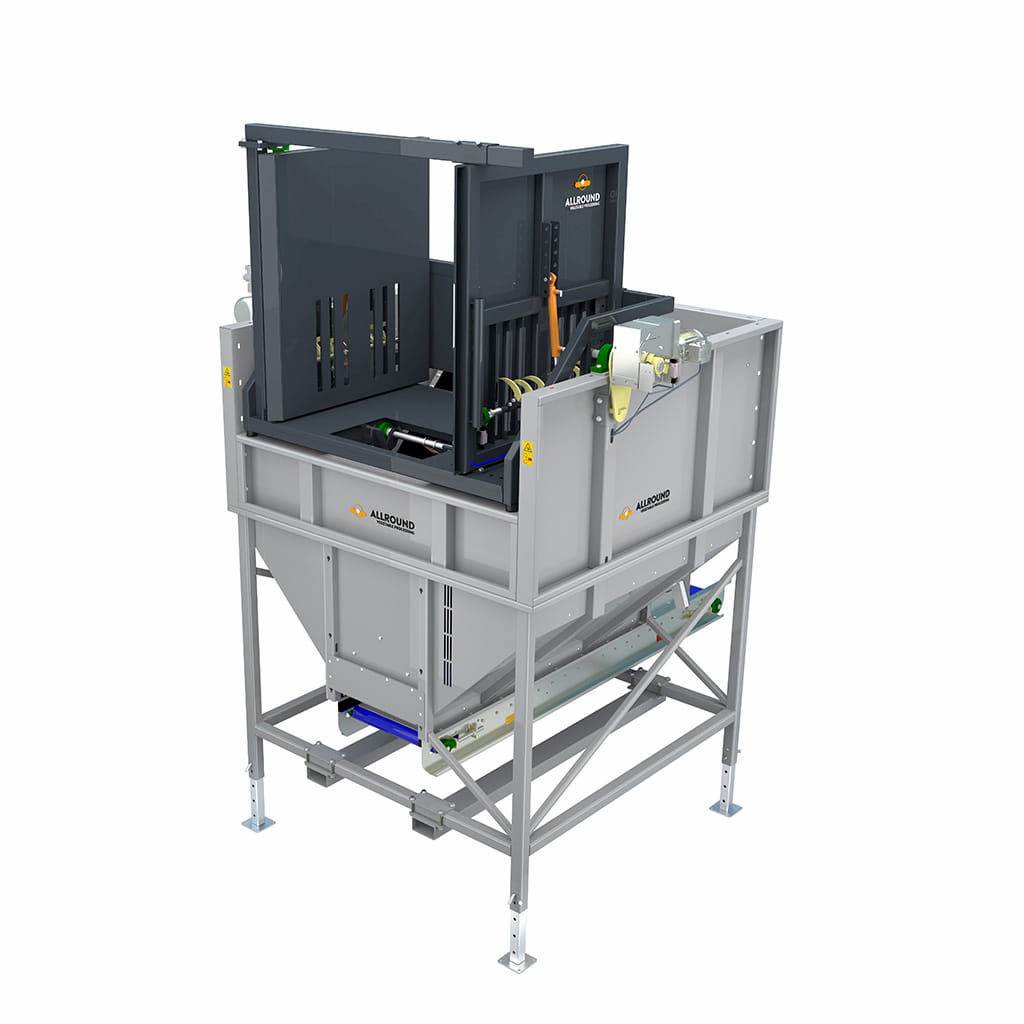

Drop Limit Box Tipper

The drop limit box tipper is a special box tipping system where the drop is limited, meaning that it exposes the product to less risk of being damaged due to the fall. The tilting mechanism is achieved in three steps:

1. The cubic box is placed in the machine and the crate is clamped against a cover plate.

2. The crate is tilted 135⁰ degrees.

3. Once the crate has been tilted, the coffin is pushed off the cover plate and the products roll off onto the conveyor belt.

This tilting method reduces the risk of bruising and meters the outflow of the products.

| Specs | ZD 160 |

|---|---|

| Width of Boxes (mm) | 1600 |

| Max Height (mm) | 3100 |

| Height in Lower Position (mm) | 2590 |

| Width (mm) | 3000 |

| Max Angle | 135° |

| Max Lifting Weight (kg) | ca. 1500 |

| Drawing | View |

Reverse Box Tipper

The reverse box tipper mechanism tips the empty box at an initial angle. While the empty box is being filled, it slowly tips back minimizing any product damage.

| Specs | ZR 160 |

|---|---|

| Width of Boxes (mm) | 1600 |

| Max Height (mm) | 2300 |

| Height in Lower Position (mm) | 1220 |

| Width (mm) | 2056 |

| Sensor | yes |

| Max Lifting Weight (kg) | ca. 1250 |

| Drawing | View |

Cabbage Box Tipper

The cabbage box filler is designed to minimize the height of the drop of the products. This is achieved by tilting the box onto a belt which gently feeds the line.

| Specs | ZC 160 |

|---|---|

| Box Width (mm) | 1600 |

| Max Height (mm) | 2700 |

| Height in Lower Position (mm) | 1970 |

| Width (mm) | 2200 |

| Dosing System | Automatic |

| Hydraulic Pressure | 180 bar |

| Drawing | View |